Steel Making

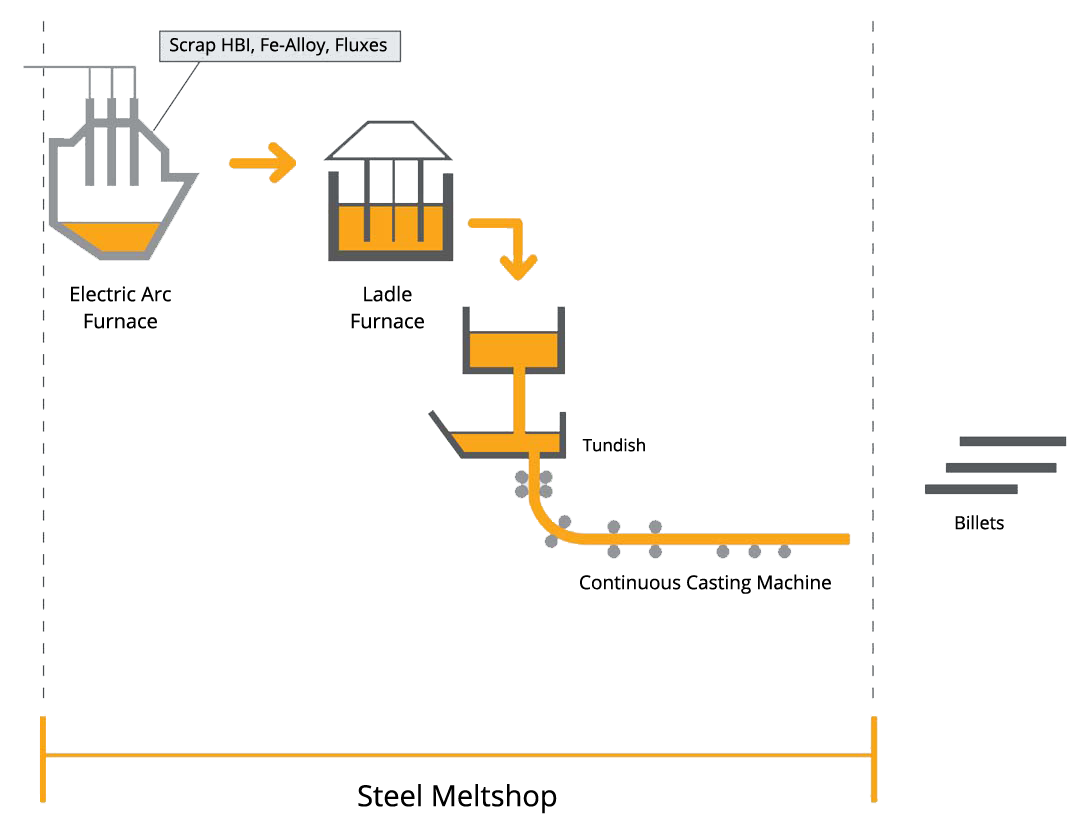

The steel meltshop in Amsteel Mills Klang was established in 1982 with an 85-ton Electric Arc Furnace (EAF), subsequently upgraded to 100-ton, and a 6-strand Continuous Casting Machine (CCM) to produce billets. The Ladle Furnace (LF) was installed in 1985 as part of our mills’ quality improvement programme to produce high grade billets.

Amsteel Mills’ meltshop in Banting comprises a 160-ton Direct Current EAF, LF, Vacuum Oxygen Deggasing (VOD) and a 6-strand CCM featuring full shroud or submerged nozzle operation (stopper rod system), mould EMS and hydraulic oscillators. The 10m radius casting machine is designed for high speed casting of 130mm to 160mm billets in a wide range of special engineering steel including free-cutting and cold heading quality for the downstream industries.